Fast, Reliable Emergency Gearbox Repairs to Minimize Downtime ⚙️⏳

When your industrial gearbox fails, every second of downtime costs your business time and money. At Texas Gear Repair.net, we offer 24/7 emergency gearbox repair services, ensuring your operations stay on track with rapid diagnostics, precision repairs, and expedited turnaround times.

Our experienced technicians specialize in critical gearbox restorations, helping industries like power plants, oil & gas, manufacturing, steel mills, mining, and heavy machinery recover from unexpected failures. With advanced machining, engineering expertise, and a commitment to fast service, we’ll have your gearbox running at peak efficiency in no time.

Rapid Industrial Gearbox Repair for Critical Operations 🚀

We understand that unexpected failures require immediate solutions. That’s why we provide:

✅ 24/7 Emergency Gearbox Repair – Fast response times to reduce unplanned downtime.

✅ On-Site Gearbox Inspection & Analysis – Our experts evaluate your equipment at your facility or in our workshop.

✅ Precision Machining & Component Rebuilding – We restore or replace worn gears, shafts, and bearings to OEM standards.

✅ Expedited Turnaround Without Compromising Quality – Get back to full production faster with rush service options.

✅ Reverse Engineering & Custom Gear Solutions – No obsolete part? No problem. We reverse-engineer components to match your exact specifications.

Emergency Gearbox Repair Services We Offer 🔩🏭

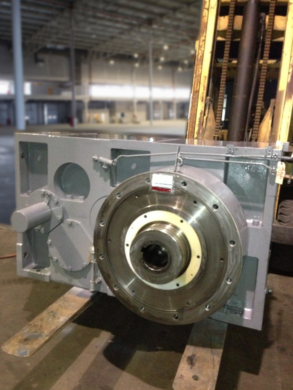

We specialize in emergency repairs for a variety of industrial gearbox types, including:

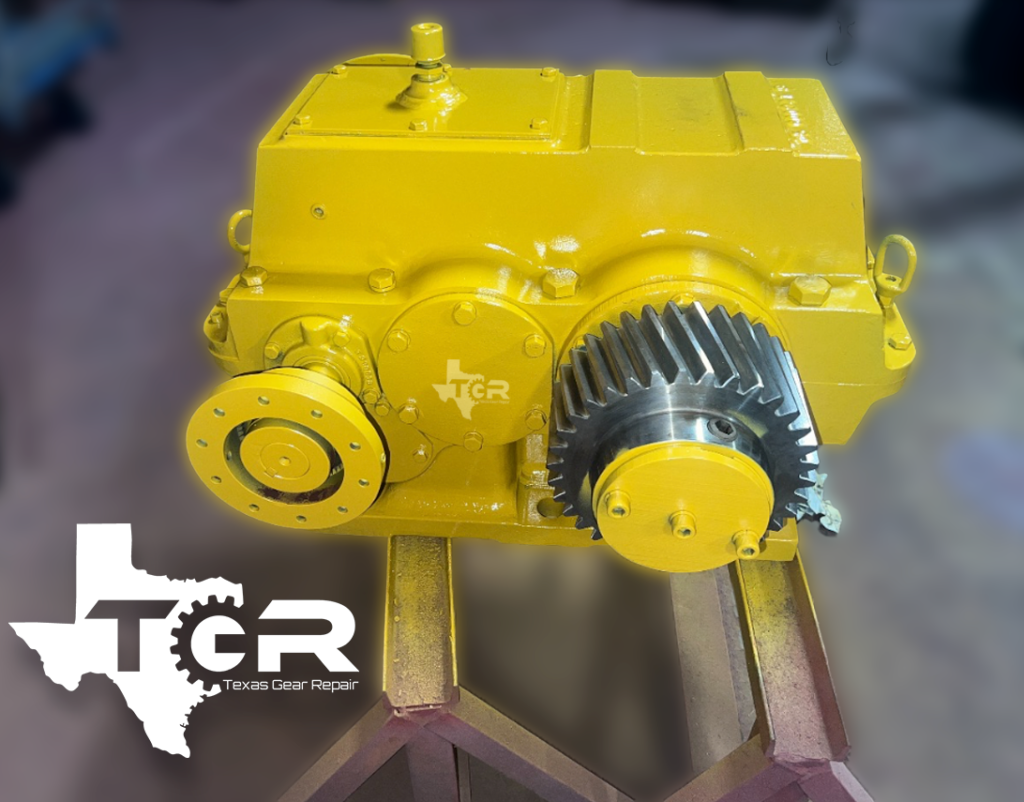

⚙️ Helical Gearbox Repair – For high-load, high-torque applications.

⚙️ Spur Gearbox Rebuilding – Designed for precision and durability.

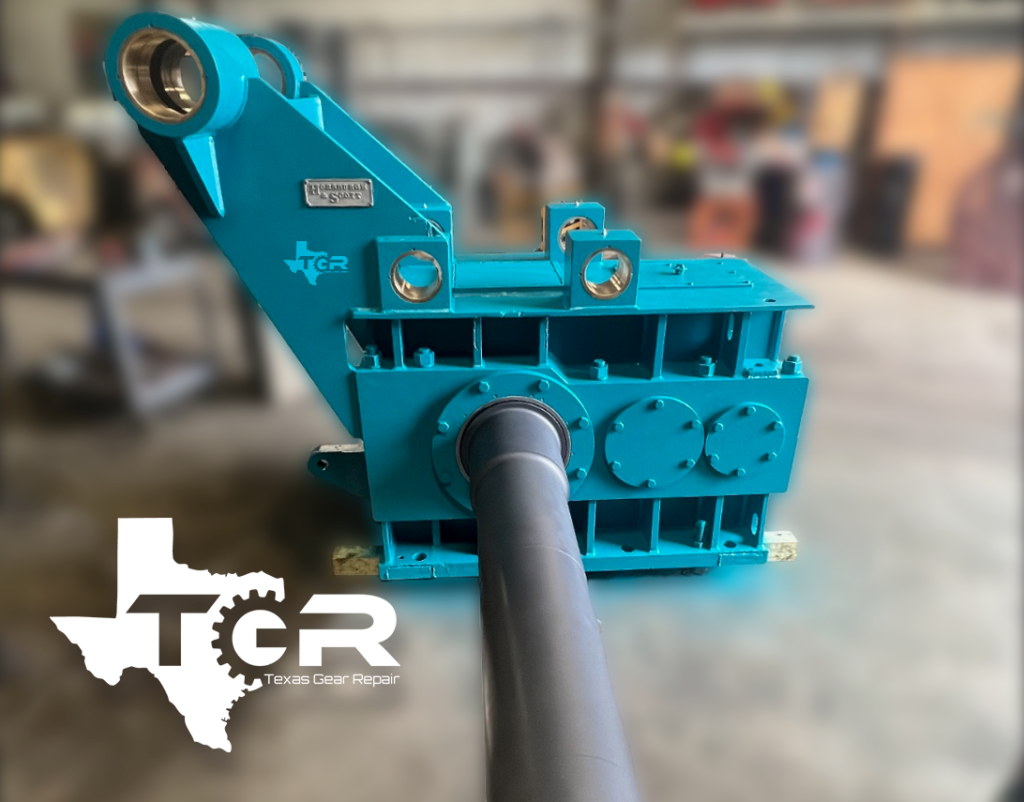

⚙️ Bevel Gearbox Restoration – For power transmission at right angles.

⚙️ Worm Gearbox Overhaul – Ensuring smooth operation and longevity.

⚙️ Planetary Gearbox Reconditioning – Built for maximum efficiency in compact designs.

⚙️ Custom & Specialty Gearbox Repair – No matter the size, type, or complexity, we can restore and optimize your gearbox.

Our Emergency Repair Process – Get Back Online Fast 🔧⏩

⏳ Step 1: Rapid Diagnosis & Damage Assessment

- We begin with an immediate inspection, identifying critical failures such as broken gear teeth, misalignment, overheating, or lubrication issues.

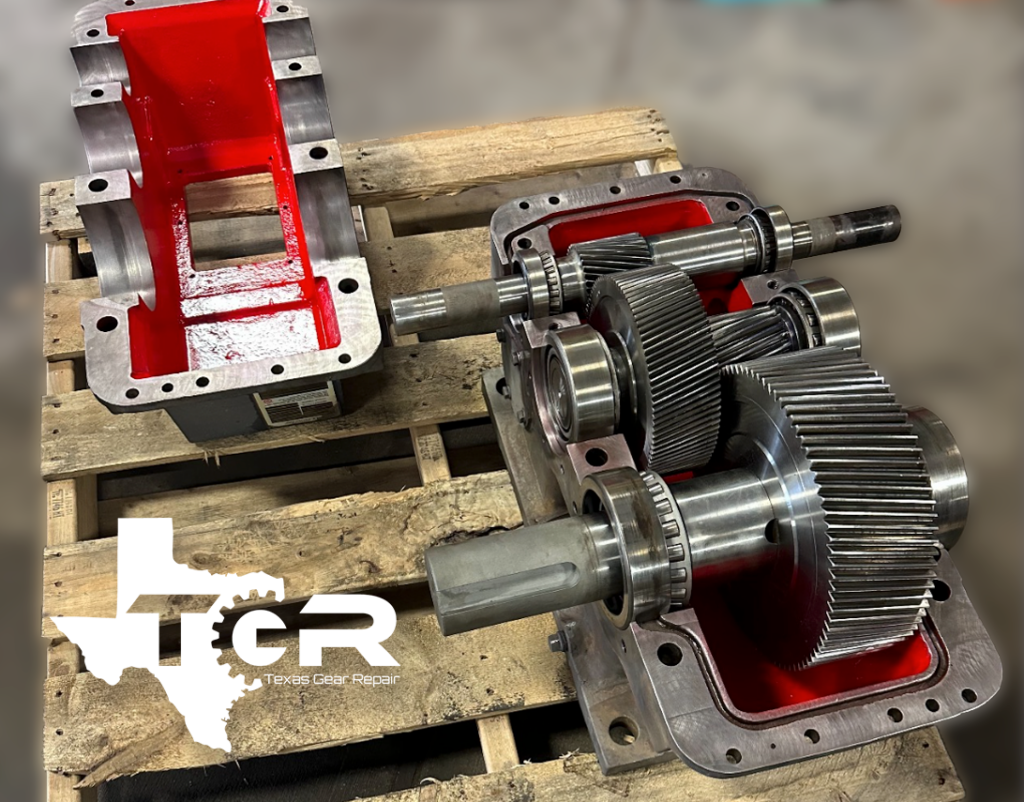

🛠️ Step 2: Gearbox Disassembly & Component Repair

- Worn gears, shafts, and bearings are restored using advanced CNC machining, grinding, and reconditioning techniques.

- If parts are beyond repair, we offer custom fabrication or reverse engineering to recreate obsolete components.

🔥 Step 3: Heat Treatment & Strength Enhancement

- We harden and coat gear surfaces to increase wear resistance and operational longevity.

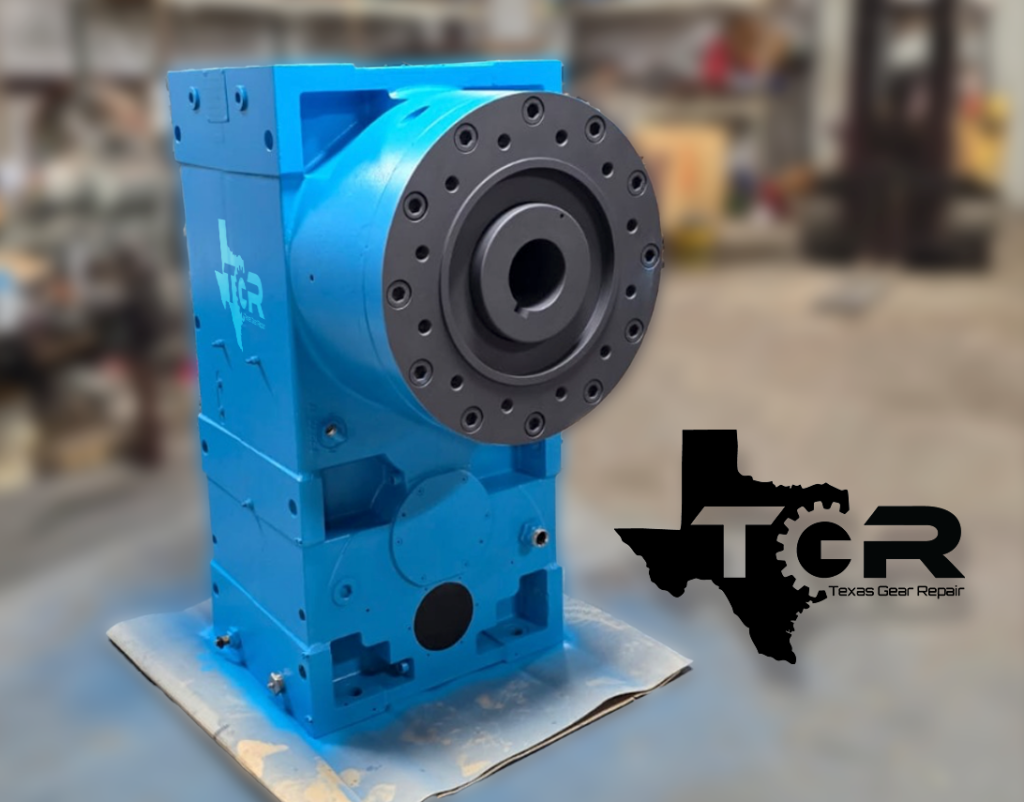

📏 Step 4: Precision Reassembly & Load Testing

- Every gearbox is rigorously tested to ensure alignment, proper lubrication, and peak performance before returning to service.

Why Choose Texas Gear Repair.net for Emergency Gearbox Repairs?

✅ 24/7 Emergency Response – We’re ready when you need us, day or night.

✅ Fast Turnaround to Reduce Downtime – Rush repair services get you operational ASAP.

✅ Expert Engineers & Machinists – Backed by decades of industrial gearbox expertise.

✅ On-Site & Nationwide Service – We offer on-location assessments or full repairs in our state-of-the-art facility.

✅ OEM-Quality Repairs Without the High Cost – Avoid expensive gearbox replacements with our cost-effective solutions.